OEM Clothing Manufacturer

Clothing production is complicated. Often a jacket that looks very simple will have more than 10 suppliers, such as fabric supplier, zipper supplier, webbing supplier, button supplier, ribbing Suppliers, quilted suppliers, tag suppliers, packaging bag suppliers, washed label suppliers, embroidery suppliers…There are also many problems encountered in the production process, such as color difference and size problems. The sewing line is uneven, and the problem of shrinkage after washing… As a professional Man Clothing manufacturer, we are a one-stop-shop for all your problems.

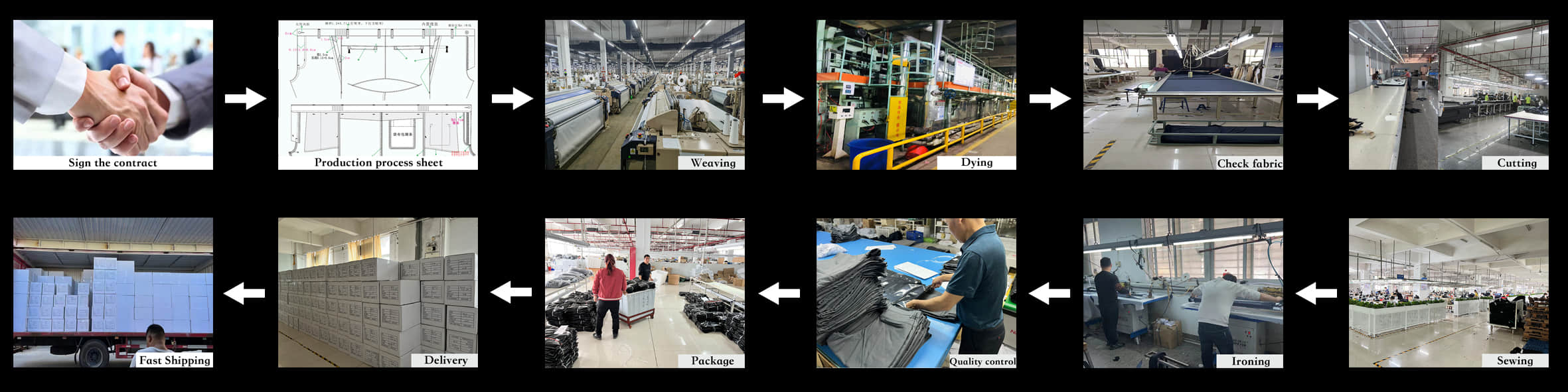

We have finely split the OEM process. After receiving customer samples, we will analyze the structure and processing technology of the clothing product, and then perform the design of the pattern, the specifications of the finished product, the cutting process, the sewing process, and the ironing. Standard technical documents have been developed for each production link such as packaging, ironing, etc., so as to produce garments that are of high quality, quantity, low cost, and meet the needs of consumers and customers.

What is OEM CLOTHING?

The cooperation method of entrusting others to produce is OEM, and the manufacturer that undertakes this processing task is called an OEM manufacturer. OEM products are tailor-made for the brand manufacturer, and only the brand name can be used after production, and it must not be named Produces under the producer’s own name. We produce your brand for you behind your back.

Our Production Capacity And Machinery

– 300 Flatcars: divided into computer flat cars and ordinary flat cars, used for sewing and stitching, crimping, —- opening bags, installing collars, installing sleeves, installing zippers, etc.;

– 180 Three-line edging cars: used for ordinary edging;

– 180 Four-line overwrapping cars: mostly used for overwrapping of knitted or elastic parts;

– 150 Five-line edging cars: It has a chain bottom, which is mostly used by high-end customers, depending on customer requirements;

– 8 Double stitching cars: mostly used in jackets, casual pants, jeans, and double-threaded;

– 8 Cut and repair the cars: also called the cut and stop the car, some parts are used for cutting the mouth;

– 2 Chain cars: Used by high-end customers, it is generally used to reinforce the strength of the seam;

– 2 Trouser cas: for waistband;

– 2 Trouser ear carts: specially used for pulling trouser ears;

– 4 Button nailing machine: for button nailing;

– 1 Computerized button door car: automatic button door opening, for opening buttonholes

– 2 Eichhornia carats: for phoenix eyes;

– 2 Four-in-one deduction casr: special for four-in-one deduction;

High-Quality Fabrics

Military uniforms require the toughest fabrics that can withstand the elements while being comfortable to wear. We manufacture army jackets with the best quality fabrics in the market to ensure maximum protection. As a customer-centric military uniform manufacturer, we can also use your specified fabrics for production.

High-Quality Fabrics

Military uniforms require the toughest fabrics that can withstand the elements while being comfortable to wear. We manufacture army jackets with the best quality fabrics in the market to ensure maximum protection. As a customer-centric military uniform manufacturer, we can also use your specified fabrics for production.

High-Quality Fabrics

Military uniforms require the toughest fabrics that can withstand the elements while being comfortable to wear. We manufacture army jackets with the best quality fabrics in the market to ensure maximum protection. As a customer-centric military uniform manufacturer, we can also use your specified fabrics for production.

High-Quality Fabrics

Military uniforms require the toughest fabrics that can withstand the elements while being comfortable to wear. We manufacture army jackets with the best quality fabrics in the market to ensure maximum protection. As a customer-centric military uniform manufacturer, we can also use your specified fabrics for production.

OEM Clothing FAQ

# What is your minimum order quantity for OEM?

Our recommended minimum order quantity is 1000pcs/model for OEM. Considering your sales situation, we can customize different colors for you, but the same style , about 1000 pieces, is the most cost-effective. 300 pieces we can also customize for you, but the cost will be higher than 1000 pieces.

# How do you arrange production?

We will arrange the production line reasonably according to the order quantity. If the style is complicated and the order is large, then we will arrange a large line of about 30 people to produce. If your order is relatively small, then we will arrange a small production line with about 10 people to produce.

# I have a photo, can you produce it?

We can make pattern based on your photos, but you need to provide a size table. And cooperate with us to choose fabrics and accessories. After the samples come out, we need to communicate to make improvements, and then proof again to confirm. This is a very long and complicated process that requires the understanding and patience of both parties.

# What is your maximum production capacity?

We are good at mass production of basic jackets. Our monthly production capacity is 5,000 pieces. If your order is very large and the delivery time is very tight, it will be no problem to leave it to us.

# What we do not produce?

We produce all types of jackets and pants. But we do not produce all textiles, we do not produce sweaters, yoga clothes, hats, socks, scarves, but we can recommend you to work with a factory that specializes in the production of these items. If you are not sure whether we produce it, just send an email to inquire.

# I like one of your white-label garments and blank clothing, but can I change the color?

Changing the color requires re-production. We need to purchase fabrics and accessories for you again. To manufacturer, the process is the same as the production of bulk goods. If the quantity is not large, we do not recommend changing the color. The MOQ for changing the color is 300, and the price will be higher than the normal blank jacket. We need to calculate the specific price according to the style and quantity.

# I hope to print my own brand on the blank jacket, can I?

Generally speaking, we can print your logo or brand for single-layer clothes, and we can also embroider your brand for you. It is not recommended to print double-layer clothes, because the printing process is due to the lining and face cloth. Friction between two fabric will have a destructive effect on the printing effect.

# Is it possible to provide standard modification services?

Yes, for our white-label garments, normally we will reserve an empty hem at the back of the neck so that you can sew your logo. For the standard change service, we will ask customers to pay for the production cost of the trademark, because we do not produce trademarks, we need to purchase trademarks.